Understanding Forklift Controls: Acceleration, Braking, Hydraulics, and More

Posted by: admin on March 24, 2025

Mastering forklift controls is crucial for both efficiency and workplace safety. Each function, from steering to hydraulic lifts, contributes to a machine’s overall performance. OSHA, the authority on workplace safety, emphasizes control training as an essential part of certification, ensuring operators handle these machines with confidence. For those preparing for their certification, forklift safety training provides the foundation needed to meet regulatory requirements.

What Are Forklift Controls?

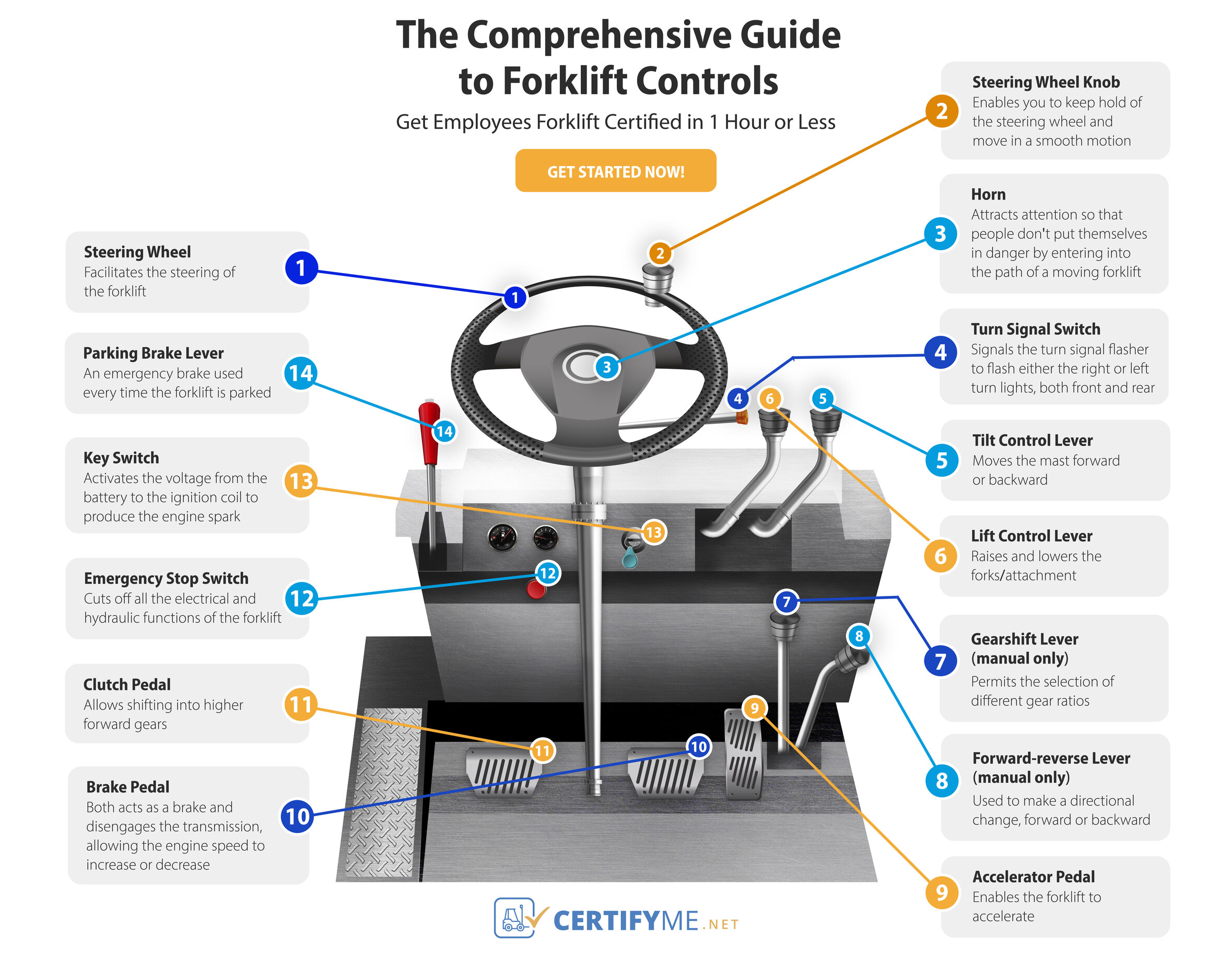

Operators interact with various control mechanisms to maneuver and manage loads effectively. A forklift controls diagram typically illustrates the essential components, such as:

- Steering Mechanism: Allows directional movement.

- Braking System: Includes the service brake and parking brake for stopping and securing the forklift.

- Hydraulic Lifts: Raises, lowers, and tilts loads as needed.

- Acceleration Pedal: Regulates speed and movement.

- Directional Lever: Switches between forward and reverse functions.

Understanding these components is necessary for smooth operation, especially when transitioning between different forklift models.

Types of Forklift Controls You Need to Know

Types of Forklift Controls You Need to Know

Acceleration and Braking

Forklift acceleration and braking systems directly impact safety. The accelerator pedal manages speed, while the primary brake brings the vehicle to a stop. Many forklifts also feature an inching pedal, which allows precise movement without fully disengaging the drive system.

Hydraulic Controls

Hydraulic systems control lifting, tilting, and shifting operations. These include levers for fork height adjustments, mast tilting, and side-shifting to align loads with precision.

Direction Levers

These levers control forward and reverse movement. The parking brake, often a separate pedal or hand lever, secures the forklift when stationary.

Safety Guidelines for Operating Forklift Controls

Compliance with OSHA forklift control training standards ensures operators understand control mechanisms before getting behind the wheel. Key safety measures include:

- Inspecting controls before each shift to identify wear or malfunctions.

- Keeping acceleration smooth to avoid sudden movements.

- Using hydraulic controls gradually to prevent load instability.

- Engaging the parking brake when stepping away from the forklift.

Following these precautions reduces accident risks and extends equipment lifespan.

Troubleshooting Common Forklift Control Issues

Equipment malfunctions can disrupt workflow and create hazards. Common forklift control issues include:

- Slow hydraulic response: Check fluid levels and inspect for leaks.

- Unresponsive acceleration: Verify throttle linkage and look for obstructions.

- Braking inconsistencies: Inspect brake pads and hydraulic pressure.

- Erratic steering behavior: Assess tire conditions and alignment.

Routine maintenance and timely troubleshooting keep operations running smoothly.

How to Become Proficient with Forklift Controls

Hands-on experience is vital for developing skillful control. OSHA-approved programs provide structured training that covers all essential functions, from how to drive a forklift to advanced maneuvering techniques such as navigating ramps and handling uneven surfaces. Practical instruction helps reinforce theoretical knowledge, ensuring operators can confidently handle different forklifts.

FAQs About Forklift Controls

What are the most critical forklift controls to learn?

Mastering acceleration, braking, and hydraulic functions is essential. These systems form the foundation of forklift operation.

How do you troubleshoot a forklift with unresponsive hydraulic controls?

First, check fluid levels. If the problem persists, inspect hydraulic hoses and pump connections for leaks or blockages.

Do OSHA regulations require specific training for forklift controls?

Yes, OSHA mandates that operators receive formal instruction and evaluation to ensure safe control handling in the workplace.

CertifyMe: Your Partner in Forklift Training

Effective control management is critical for compliance and safety. Training programs from CertifyMe equip operators with the expertise to operate forklifts confidently. Enroll today and ensure workplace safety while meeting OSHA standards.

Welcome to CertifyMe.net

CertifyMe.net has offered online forklift certification since 1999. With Our Convenient online program. your employess can earn their certification in an hour or less.

Browse Online Certifications:

This low-cost program can be compeleted anytime, anywhere!