Forklift Maintenance Requirements: OSHA Daily Checklist and Inspection Tips

Posted by: admin on April 12, 2025

Forklift maintenance requirements protect workers, reduce accidents, and ensure full compliance with OSHA regulations. Meeting the right forklift maintenance checklist standards matters for every company operating lift trucks. Staying proactive with forklift maintenance prevents costly repairs, avoids downtime, and keeps your operators and equipment safe. Proper forklift training strengthens maintenance programs—learn more about forklift maintenance requirements to stay compliant.

Forklift maintenance requirements protect workers, reduce accidents, and ensure full compliance with OSHA regulations. Meeting the right forklift maintenance checklist standards matters for every company operating lift trucks. Staying proactive with forklift maintenance prevents costly repairs, avoids downtime, and keeps your operators and equipment safe. Proper forklift training strengthens maintenance programs—learn more about forklift maintenance requirements to stay compliant.

Why Forklift Maintenance Matters

Forklifts endure heavy loads, tight turns, and long operating hours, which means wear and tear happens fast. Ignoring forklift maintenance leads to dangerous mechanical failures and increased workplace accidents. Following a forklift maintenance checklist creates safer job sites while protecting companies from major OSHA penalties.

What Are OSHA Forklift Maintenance Requirements?

Daily inspections are mandatory under OSHA’s forklift maintenance requirements. Every forklift must be checked before the first use of each shift. OSHA defines proper maintenance as checking for operational safety, removing damaged equipment, and immediately addressing any defects. Skipping forklift maintenance can lead to serious penalties—current fines can easily exceed $15,000 per violation.

Building a Forklift Maintenance Checklist

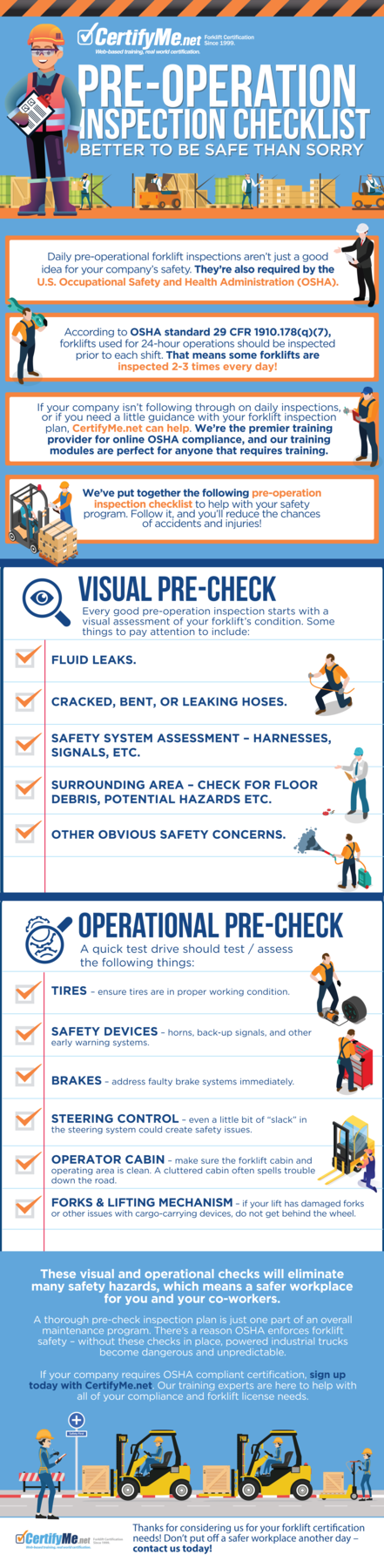

A thorough forklift maintenance checklist forms the foundation of safe operation. Key items to inspect include:

- Tire condition and pressure: Look for flat spots, embedded debris, or worn treads.

- Warning devices: Test horns, backup alarms, lights, and gauges for full functionality.

- Load-handling systems: Ensure forks are straight, free of cracks, and securely attached.

- Fluid levels: Check oil, hydraulic fluid, coolant, and fuel for leaks or low levels.

- Brake systems: Verify proper pedal resistance and parking brake engagement.

Weekly and monthly inspections should include deeper evaluations of hydraulic hoses, chains, mast components, and steering mechanisms.

Understanding Forklift Maintenance Schedules

Forklift maintenance schedules vary based on manufacturer guidelines and OSHA expectations. Daily inspections are non-negotiable. However, heavy-use environments demand even more frequent service intervals. Dusty, cold, or high-humidity conditions accelerate wear and may require shortened maintenance schedules to protect forklift integrity.

Critical Forklift Maintenance Procedures You Cannot Ignore

Overlooking core forklift maintenance procedures results in expensive damage or life-threatening incidents. Critical tasks include:

- Inspecting hydraulic hoses: Replace any hose showing bulges, cracks, or soft spots.

- Checking stability systems: Examine tilt cylinders, lift chains, and mast rollers for smooth operation.

- Monitoring battery health: Ensure proper water levels, tight cable connections, and clean terminals on electric forklifts.

Catching small issues early prevents larger, costlier repairs.

Forklift Inspection Penalties: What Happens When You Skip Maintenance?

Failing to complete daily inspections or address known issues exposes businesses to massive liability. OSHA regularly levies fines against employers who neglect forklift maintenance, often exceeding $15,000 per offense. Beyond fines, businesses risk civil lawsuits, higher insurance premiums, and reputational damage following an avoidable forklift incident.

FAQs About Forklift Maintenance and OSHA Compliance

How often does OSHA require forklift inspections?

Forklift inspections must occur before each shift, without exception. Scheduled maintenance is separate and must follow manufacturer instructions.

What must be on a forklift inspection checklist?

Tires, forks, lights, brakes, steering, fluids, and load-handling systems all require inspection daily.

What happens after a failed forklift inspection?

The forklift must be removed from service immediately until repairs or replacements are completed.

Can companies be fined without an accident happening?

Yes. OSHA penalizes missing records, skipped inspections, and mechanical defects—even when no injury occurs.

Penalties for Not Following OSHA Forklift Inspections

OSHA requirements for forklift inspections are in place for a reason – to keep everyone safe. If you fail to adhere to the rules for OSHA forklift inspection checklists, your company is subject to severe fines and penalties.

For example, if a forklift driver is involved in an accident and OSHA proves you didn’t follow OSHA forklift inspections, you could receive a fine exceeding $10,000! As of January 2019, OSHA announced their new fines and penalties, which include serious violations up to $13,260.

For “willful or repeated” violations, including OSHA requirements for forklift inspections, the fine is roughly ten times the amount of a serious violation: $132,598.

Simply put, can’t afford to ignore OSHA forklift inspections.

Protect Your Workplace with CertifyMe

Meeting forklift maintenance requirements forms just one part of a safe, compliant work environment. Proper forklift certification ensures drivers recognize mechanical issues before they become disasters. CertifyMe’s affordable online forklift certification program helps businesses meet OSHA rules with 24/7 training access and free three-year renewals. Strengthen your safety culture today with CertifyMe.

Welcome to CertifyMe.net

CertifyMe.net has offered online forklift certification since 1999. With Our Convenient online program. your employess can earn their certification in an hour or less.

Browse Online Certifications:

This low-cost program can be compeleted anytime, anywhere!