The Fundamentals of the Forklift Stability Triangle

The U.S. Occupational Safety and Health Administration (OSHA) considers forklift stability one of the most important parts of safe operation of powered industrial trucks. Since all forklifts are classified as powered industrial trucks, it’s imperative that all forklift operators understand the basic concepts of the forklift stability triangle.

What is the Forklift Stability Triangle?

According to OSHA’s powered industrial truck e-tool, forklift stability ranks right up there with safe load capacity, balance, and maximum load requirements. But what exactly is the forklift stability triangle? This shape (and overall concept) is based on three different locations on a standard forklift:

According to OSHA’s powered industrial truck e-tool, forklift stability ranks right up there with safe load capacity, balance, and maximum load requirements. But what exactly is the forklift stability triangle? This shape (and overall concept) is based on three different locations on a standard forklift:

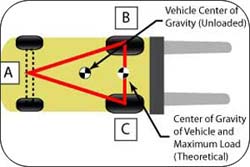

- Point A: pivot point on rear axle

- Point B: left front wheel

- Point C: right front wheel

Now, draw a triangle to connect these three points. As long as the forklift’s center of gravity remains somewhere in this “stability triangle,” OSHA considers this a well-balanced forklift. Once the load shifts outside the forklift stability triangle, the lift can tip over.

Determining the Stability Triangle for Forklifts

While the above information is nice to know, it’s theoretical in nature. Understanding how to use the stability triangle for forklifts practically is important. Tip-overs are possible when operators fail to factor the stability triangle into their daily duties. There are two main factors that impact the forklift’s balance:

Center of Gravity

To avoid tip-overs, work to distribute weight evenly when carrying irregular loads. Keep the center of gravity of the load as close to the center as possible going horizontally across your forks. By doing so, you’ll reduce the risk of goods and equipment being damaged in an accident.

Shifting Center of Gravity

Every time a load is placed on a forklift, the center of gravity shifts forward. So long as weight restrictions aren’t ignored and the load is centered on the forks, the forklift will not tip over. When a load is too heavy or not placed in the center of the forks, though, accidents can happen.

Practical Stability Triangle Tips

To safely ensure the stability triangle is in effect, follow these practical tips:

1. Never Exceed the Weight Capacity on the Forklift’s Data Plate

Oversized, irregularly shaped cargo can cause the forklift’s capacity to be exceeded, causing tip-overs.

2. Position the Load As Close to the Front Wheels As Possible

This helps minimize the load distance and load the heaviest part by the mast.

3. Drive Slow When Handling Extra Heavy Loads

When handling an oversized load that’s close to capacity, carry at the lowest position possible and accelerate slowly and evenly. This helps ensure the integrity of the forklift stability triangle.

4. Should the Forklift Begin to Tip, Avoid Jumping

You could be crushed by a toppling load or forklift. Instead, brace yourself and keep all body parts inside the operator area.

Why Forklift Stability Training Matters

Workers need a solid understanding of the stability triangle before they begin using forklifts on the job. With a comprehensive understanding of how load balance impacts forklift trucks, operators are bound to get in over their heads. OSHA standard 29 CFR 1910.178 Appendix A sets the safety guideline for everything related to the forklift stability triangle, including effective training methods to help ensure all forklift operators understand this crucial safety concept.

Forklift stability triangle training includes all the OSHA requirements necessary to grasp the concept in a variety of circumstances, including:

- Proper turning techniques

- Load stability – best practices

- Stability maintenance

- Safe speed for forklift stability triangle center of gravity considerations

- And much more

Sign Up for Forklift Stability Training Now

CertifyMe.net offers comprehensive forklift stability triangle training for new and experienced operators alike. In fact, those who sign up for our training will learn the ins and outs of all aspects of forklift use.

Our regular training class and Train a Trainer course offer thorough forklift stability triangle training for anyone that operators a forklift. We offer free three year renewals, too. For more information, visit our contact page or call us today at 888-699-4800.

Follow step-by-step instructions to get OSHA compliant!

This low-cost program can be completed anytime, anywhere!